HOT DRAPE FORMING PLANT

TEATEK CUSTOM PLANTS

YEAR: 2020

CUSTOMER: LEONARDO

PLANT: POMIGLIANO D’ARCO (NAPOLI)

Design and construction of a plant for Hot Drape Forming activities for carbon fiber parts

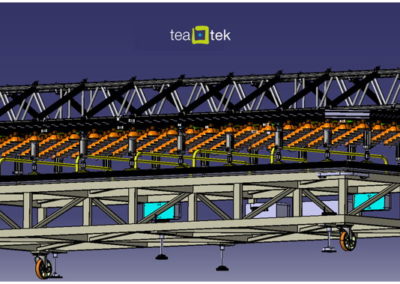

The plant, called HDF4, allows to carry out the “hot forming” phase of the carbon fiber parts which, resting on special mandrels, undergo a heat treatment in the presence of vacuum which allows them to assume the final shape (determined right from the spindle), waiting for the “cooking” in the autoclave.

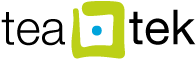

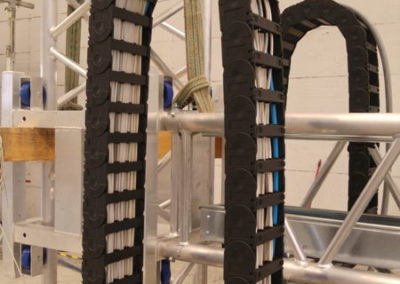

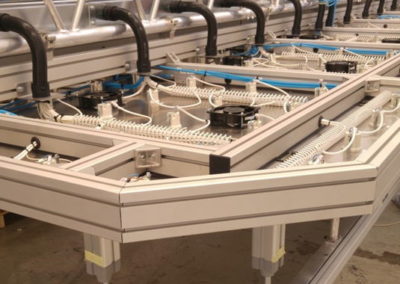

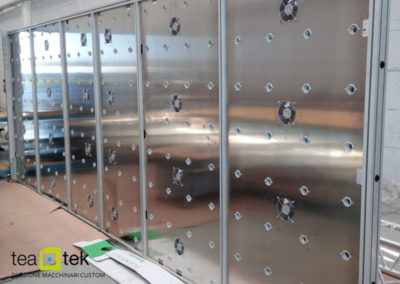

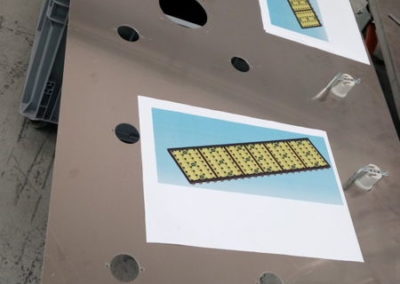

The HDF4 consists of a load-bearing structure made with two vertical trusses and a horizontal structure also composed of modular and assembled aluminum trusses, which supports the heating system (matrix of lamps individually controlled by PLC) and that of cooling, to carry out the different cycles required.

A frame is connected to the horizontal structure on which a silicone membrane is fixed, used to create the vacuum conditions when the parts are in position on the specially designed tables.

The Hot Drape Forming process is managed from an operator panel via PLC, with a user-friendly interface that allows maximum configurability in terms of switching on the lamps, movement along the Z axis and timing of the processes, to ensure that all the different families of details can be managed with the appropriate “recipes”.

VIDEO

PRODUCTION

DESIGN

Teatek S.P.A.

REGISTERED OFFICE

NAPOLI Via S. Lucia 36 - 80132

OPERATIONALS OFFICES

NAPOLI: Via Maddaloni snc c/o Consorzio 'AREA' - 80011 ACERRA

ROMA: Contrada Piombinara snc - 00034 COLLEFERRO

MILANO*: Via Polveriera 25 - 20026 NOVATE MILANESE

*LOCATION NOT SUBJECT TO ISO VERIFICATION

teatek@adpec.it

+39 08118919610

P.IVA 06362981216